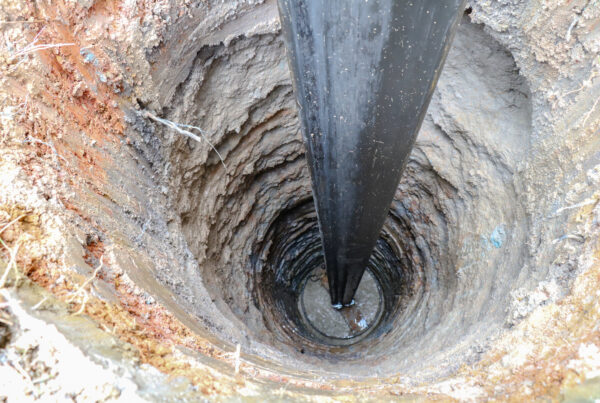

When your well pump stops working, it can feel like your lifeline has been cut. Imagine waking up to washing the dishes, only to find there’s no water—panic sets in! The good news is that reliable well pump repair services are just around the corner. Finding someone to fix your well pump quickly can help get your household back on track without too much hassle. From malfunctioning switches to clogged pipes, understanding these issues can make a world of difference. In this article, we’ll explore the essential aspects of local well pump repair services, helping you know what to look for and how to choose the best experts for your needs.

To find reliable well pump repair services near you, consider reaching out to Stevens Drilling, known for its fast and efficient service in well pump repairs. With a strong reputation and experienced technicians, we can assess and address your well pump issues promptly to ensure your water supply remains uninterrupted.

Expert Well Pump Repair Services Near You

When it comes to well pump repairs, having dependable expertise on your side is crucial. Whether it’s a sudden loss of water pressure or unusual noises emanating from the pump, these issues can disrupt your daily life in an instant. By enlisting the help of professionals like Stevens Drilling, you’re not just calling for assistance; you are tapping into years of experience and a deep understanding of various pumping systems.

One key aspect to consider is that well pumps can experience a range of problems. Some common issues include worn parts due to wear and tear, electrical failures, or even blockages caused by sediment build-up. Each scenario requires a trained eye and skilled hands to diagnose and repair efficiently. For instance, did you know that sediment can gradually clog the impeller, reducing efficiency? An expert technician can identify such problems before they escalate, saving you both time and money.

The sooner you address issues with your well pump, the better your chances are of restoring your water supply quickly.

Now, let’s talk about what distinguishes professional services. Certifications matter—a qualified technician should have valid credentials that speak to their knowledge and skills regarding multiple brands and types of pumps. This ensures that no matter the brand of your pump, you can expect quality service tailored to your specific needs.

Additionally, you want a technician who utilizes modern diagnostic equipment. Reliable professionals will have access to tools that help them assess problems accurately. With sophisticated techniques like thermal imaging, technicians can spot overheating components before they fail completely. A proactive approach means less downtime for you and prevents costly replacements in the future.

In line with this, prompt response time cannot be overstated—especially during emergencies. For residents in areas like San Antonio or New Braunfels, having a nearby expert means you won’t be left waiting long when a crisis arises. Companies like Stevens Drilling strive for quick service while maintaining high-quality standards.

For every minute without water, there’s an impact on your household or business—the faster you get help, the sooner normalcy returns.

Choosing expert well pump repair services involves checking local options like Stevens Drilling for availability and reviewing customer testimonials that reflect service quality. Consider whether they offer additional maintenance packages after the repair is done. Regular maintenance keeps your system running and helps identify potential issues before they develop into emergencies.

As you think about the vital role of well pump services, it’s important to understand some common challenges associated with these systems that users often face.

Common Well Pump Problems

One of the most alarming situations a homeowner can encounter is discovering that there’s no water flowing from their faucet. This scenario often leads to panic and confusion, but recognizing the signs early can save you time and frustration. A lack of water flow typically indicates pump failure, electrical issues, or, in some cases, a dried-up well. If your pump seems operational but no water is coming through, checking your power supply and ensuring your circuit breaker hasn’t tripped is always a good first step.

Remember that prompt action in these instances not only preserves your plumbing but also saves you money in repairs.

Another common complaint is when air starts spitting out of taps while running water. You may find this alarming as it could indicate an issue with the suction line. Air leaks interrupt the smooth operation of your system, allowing air pockets to mix in with your water supply, eventually leading to diminished water pressure. To address this effectively, inspect your suction lines for visible wear or loose connections which might be allowing air ingress.

Then there’s the frustrating situation where your well pump runs constantly and never seems to turn off. This condition often signifies a malfunctioning pressure switch or a leak somewhere in the system. Such persistent operation can lead to unnecessary wear on the pump, significantly shortening its lifespan. Industry statistics suggest that around 20% of well pump repairs are related to pressure issues, confirming this is a prevalent concern worth addressing quickly.

With an understanding of these common problems, attention can now shift toward effective measures tailored to ensure optimal performance and longevity for your well system. It’s essential to be proactive in addressing these concerns to maintain a reliable water supply.

Solutions for Leakage and Pressure Issues

When it comes to your water well system, addressing leaks and pressure problems is essential to maintaining performance as well as efficiency. A small leak might seem insignificant, but over time, it can waste gallons of water and significantly increase your utility bills. Many homeowners overlook the importance of regular inspections, only realizing the issue after it’s already caused damage.

Identifying Leaks

To catch leaks early, proactive inspection is key. Begin with a thorough examination of all visible pipes and connections. Look closely at joints and fittings where wear is likely to occur; these are the weakest points in any plumbing system. You might even use a simple soapy water solution—mix a little dish soap with water and apply it to suspect areas. If you see bubbles forming, that’s a clear signal that you have found a leak. Remember, even small leaks can lead to big problems if left unaddressed.

“An ounce of prevention is worth a pound of cure.”

What this means in the context of your water well system is that identifying leaks before they evolve into larger issues can save you significant costs down the road. Regular inspections should be part of your routine—much like checking smoke detectors; it’s an easy step that pays off immensely.

Fixing Pressure Issues

For pressure-related concerns, focus on examining the pressure tank and pressure switch first. These components play crucial roles in maintaining consistent water flow. Sometimes, simply adjusting the pressure switch settings can help; higher settings will ensure that your pump cycles properly. However, if you’re still experiencing fluctuations in water pressure after making these adjustments, it’s best to consult a professional technician.

A well-trained expert from Stevens Drilling can assess both the pump and pressure tank for any underlying damage or issues that may not be visible during your DIY checks. They possess the expertise to know what to look for and can provide tailored solutions based on their findings.

Opting for skilled services ensures that you won’t just address symptoms but tackle the root causes of any leaking or pressure issues, leading to a more reliable water supply moving forward.

Choosing a Reliable Repair Service

Not all repair services are created equal, and making an informed choice can save you money, time, and frustration. This decision becomes even more critical when it comes to something as vital as a well pump—your gateway to safe and accessible water.

Whether you’re dealing with a leak or a pressure issue, the right technician can make all the difference.

Step-by-Step Guide

First up is reading reviews. When you’re on the hunt for trustworthy services, customer feedback offers invaluable insights. Online platforms like Google or Yelp are treasure troves of information and often provide unfiltered opinions from individuals just like you. For instance, Stevens Drilling receives numerous positive testimonials that highlight their timely responsiveness and professionalism. You can gauge not just the quality of the service received but also how quickly they resolve issues—crucial factors when you’re in need of urgent help.

Following that, it’s important to verify expertise. Not all technicians possess the same level of skill or knowledge, which significantly impacts the quality of repairs. Confirm whether they have relevant certifications and experience working with various pump models and issues. You might even ask about past work or challenges they’ve successfully navigated in the field. This ensures that whoever is handling your pump knows what they’re doing.

Next, consider getting quotes from multiple services. While price should not be everything, it’s always good practice to understand how much repair services typically cost in your area. Keep this in mind: the cheapest option isn’t always synonymous with quality. Sometimes lower prices mean lower-grade parts or less experienced technicians who may lead to further complications down the line. Prioritize both value for money and quality assurance; ask questions about the parts used and warranty coverage available.

Taking these steps leads you toward making an informed selection for your well pump repairs. As you gather information to facilitate your decision-making process, remember that implementing effective strategies can further enhance your experience with potential service providers.

Preventative Maintenance Tips

Maintaining your well pump can significantly reduce the chances of unexpected breakdowns, making regular upkeep vital. Beyond the general care from professionals at Stevens Drilling, there are simple practices you can implement at home to keep everything running smoothly.

For starters, routine checks should become part of your seasonal to-do list. Regularly inspect the pressure tank and switch every few months, ensuring that all components are clean and free from debris. A buildup of dirt or rust can lead to inefficiencies, causing your system to work harder than necessary.

In addition to visual inspections, take a moment to listen to your pump. Unusual noises, such as grinding or vibrating sounds, may indicate wear or damage requiring immediate attention. Catching these signs early can help you avoid costly repairs down the road.

Regular maintenance at home sets a solid foundation, but don’t forget about the necessity of professional oversight.

Routine Checks

As someone who has lived in areas reliant on well water for years, I can tell you it’s best to become familiar with your system. Every couple of months, check in on the pressure tank and switch. This quick look ensures everything is neat and tidy; you’re checking for any leaks or signs of corrosion. Don’t shy away from getting hands-on! Ensure electrical connections are tight and secure because even a slight misalignment can affect performance.

Kenneth, a satisfied customer at Stevens Drilling, often remarks how engaging with his well system directly has improved functionality while empowering him with knowledge about his home’s water supply. He confidently tells fellow homeowners, “Stevens Drilling’s annual check-ups have kept our well system running smoothly for years.”

Did you know that well-maintained pumps have a potential lifespan of up to 15 years? However, neglecting regular upkeep might lead to failure as soon as within 5-7 years. Just imagine replacing an entire unit when you could enjoy many more years of service with a little attention!

While preventative measures will fend off most issues, it’s wise to consider what to do should repairs become inevitable.

Annual Professional Inspections

Scheduling professional inspections is invaluable for long-term health. Consider it similar to visiting a healthcare provider for a yearly check-up; it’s about maintaining wellness rather than waiting until you’re in distress. Stevens Drilling offers thorough assessments where experienced technicians meticulously check each minor detail of your system.

They’ll inspect wiring conditions, confirm the integrity of seals around pipes, and review components that often go unnoticed by casual observers. Their trained eye catches issues before they snowball into something bigger—saving you both time and money in the long run.

Recognizing potential repair needs sets the stage for understanding costs related to these essential services.

Repair Costs and Considerations

Repair costs can vary widely based on the issue and the type of pump. Understanding these costs not only helps you budget effectively but also enables you to make informed decisions regarding repairs or replacements.

Cost Breakdown

When it comes to repairs, costs are influenced by two main elements—labor and parts. On average, expect to pay between $50-$150 per hour for labor. Local services like Stevens Drilling offer competitive rates tailored to the local market, ensuring that you’re not paying an arm and a leg for skilled help.

1. Labor Costs

Labor costs fluctuate depending on the complexity of the job. A simple fix may take less time, while intricate issues may require more extensive inspections. For example, a technician diagnosing a water flow issue in your well might need to check various components thoroughly. By investing in experienced professionals, you not only save money by reducing potential errors but also ensure reliable service.

2. Parts and Components

| Component | Average Cost |

|---|---|

| Pressure Switch | $20-$40 |

| Control Box | $50-$200 |

| Well Pump | $300-$1,500+ |

When examining the cost of parts, prices can fluctuate based on manufacturer, quality, and availability. Unexpected breakdowns can lead to urgent repairs, meaning you might need to invest more quickly than anticipated.

If your pressure switch fails—critical for regulating pressure—you must act fast. While it’s relatively inexpensive compared to other parts, delayed action could lead to damage elsewhere in your pump system.

Consider Full Replacement

Sometimes, it might be more cost-effective to replace an old pump entirely rather than endure repeated repairs. This choice can save you money in repairs as well as time and hassle associated with frequent breakdowns. Regular maintenance can extend your equipment’s life; however, certain parts will inevitably reach their end. A detailed assessment by a reliable service like Stevens Drilling can guide you in deciding whether repairs are feasible or if it’s time for a new unit.

While understanding costs is crucial, knowing when to time your repairs and maintenance can also be beneficial; proactive care may prevent emergencies and save substantial dollars over time.

Overall, staying informed about repair costs and making timely decisions will ensure that you maintain your well system efficiently without overspending.